Thermal Generation Case Study

Location: Uniper Energy, Enfield Power Station, Enfield, London

Project Type: Engineering/Project Support

Sector: Industrial

About The Site:

Enfield Power Station (formally Enfield Energy Centre), commissioned in December 1999 after the completion of its construction which began in September 1997

Project Scope:

We provide our services in the following areas to ensure the smooth operation of the business.

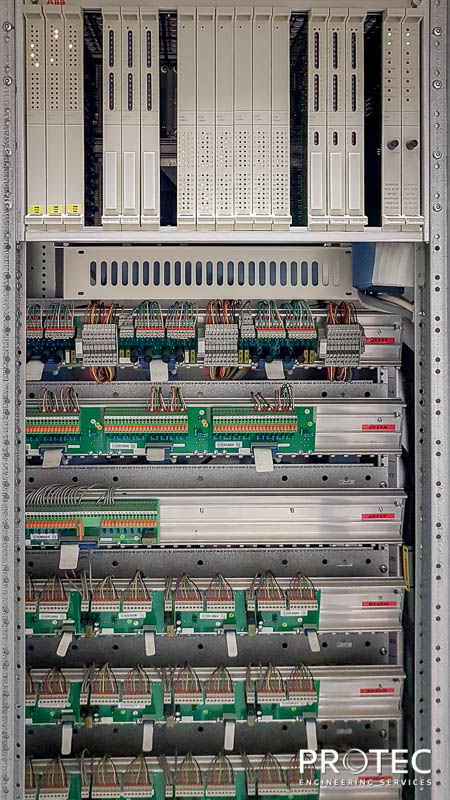

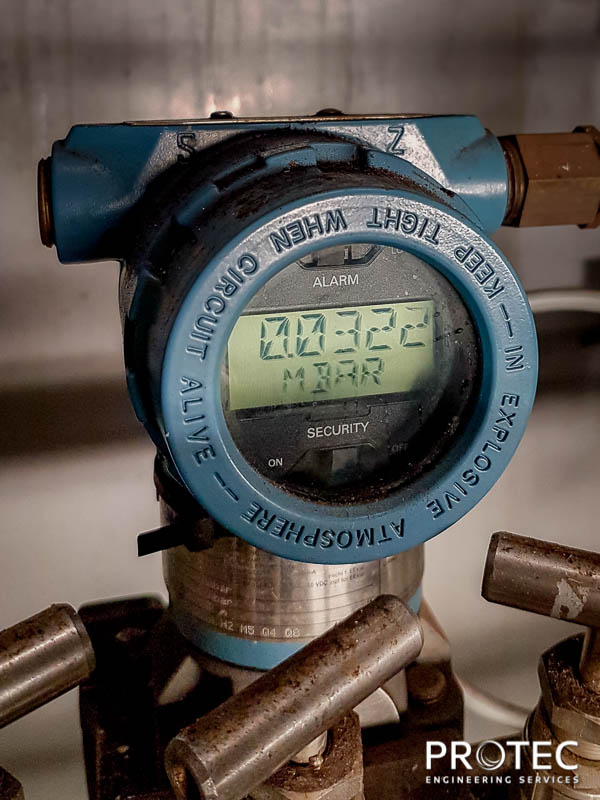

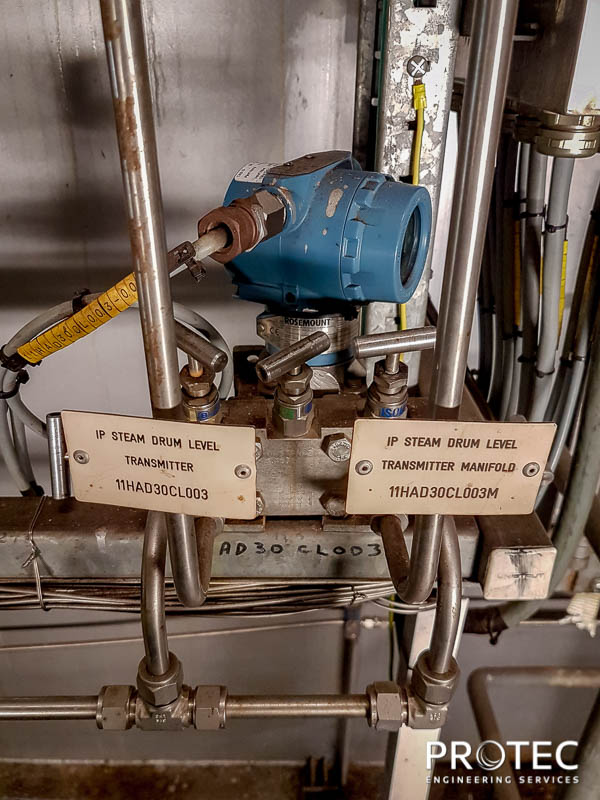

- Functional and Process Safety (SIS) Support

- BEMS Service Maintenance and Upgrade works

Engineering Services:

Provide ongoing engineering support as required.

CASE STUDY

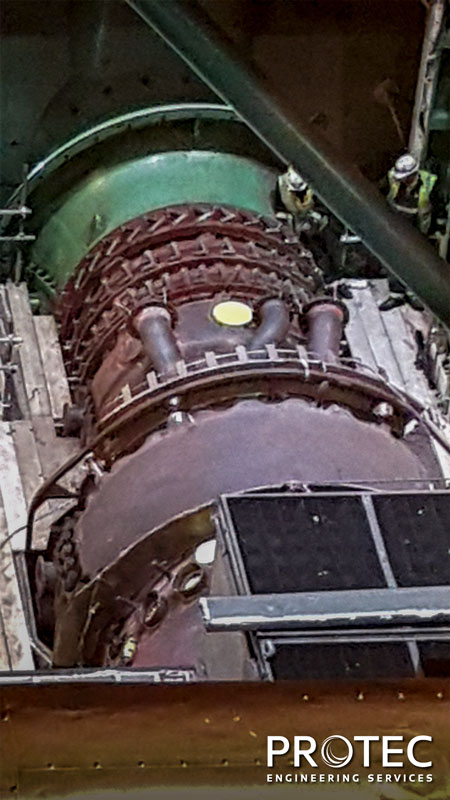

GE and Uniper Unveil 'GT26 HE' Solution, the World's First High-Efficiency Upgrade for the GT26 Gas Turbine Fleet

GE are the machine Original Equipment Manufacturer (OEM) for the GT26 which has been upgraded at Uniper Energy, Enfield.

This upgrade is a world first!

Our Managing Director was very pleased to have been part of the team supporting Uniper during the world's first HE upgrade here in the UK and Paul was happy to see some familiar faces once again and make some new acquaintances.-

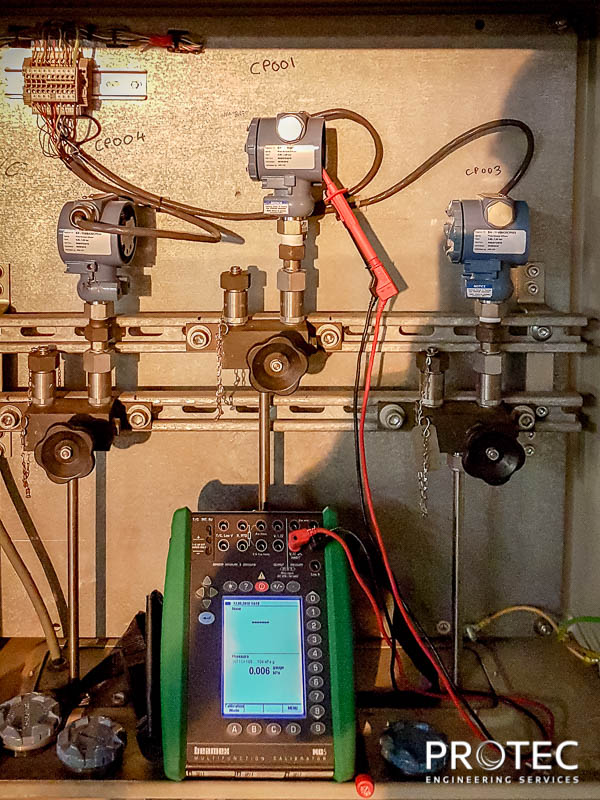

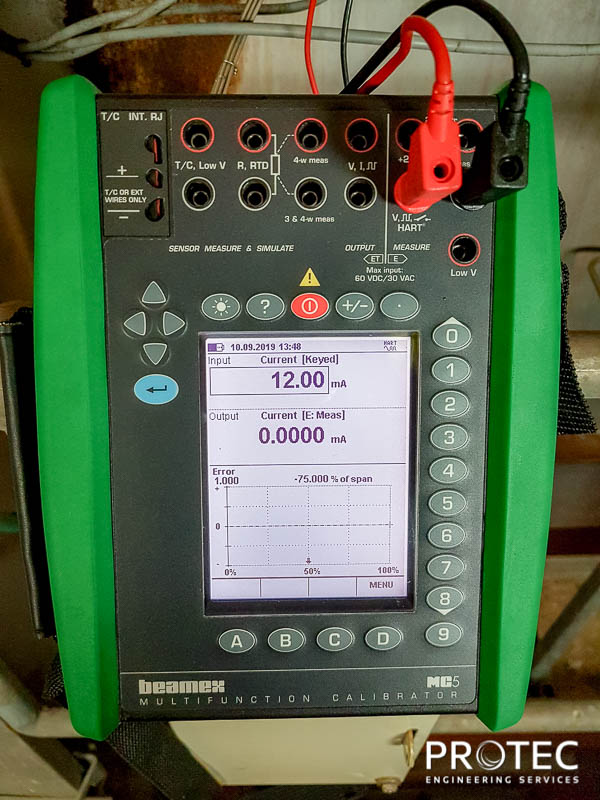

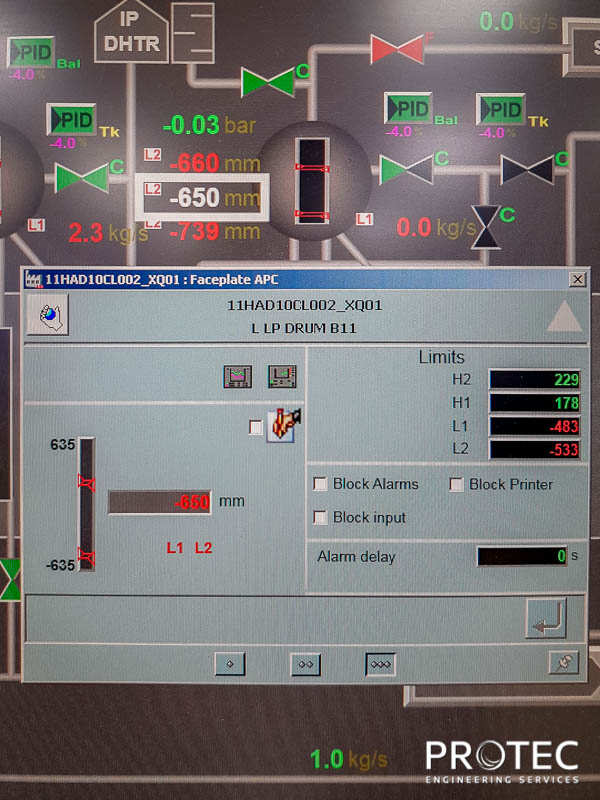

Thermal Generation Case Study Thermal Generation 012

-

Thermal Generation Case Study Thermal Generation 006

-

Thermal Generation Case Study Thermal Generation 007

-

Thermal Generation Case Study Thermal Generation 014

-

Thermal Generation Case Study Thermal Generation 005

-

Thermal Generation Case Study Thermal Generation 010

-

Thermal Generation Case Study Thermal Generation 003

-

Thermal Generation Case Study Thermal Generation 002

-

Thermal Generation Case Study Thermal Generation 001

-

Thermal Generation Case Study Thermal Generation 013

-

Thermal Generation Case Study Thermal Generation 004

-

Thermal Generation Case Study Thermal Generation 009

-

Thermal Generation Case Study Thermal Generation 011

-

Thermal Generation Case Study Thermal Generation 008

“I have worked with Protec for the last five years from day to day maintenance to project management. The level of support and quality provided has been critical to meeting project deadlines and achieving the high engineering standards set by the Power Station. Protec have shown they can work well within the site based engineering team and will be flexible to meet the requirements of the customer. I will continue to use Protec for all my engineering needs.” Matt Leech – DCS Engineer

Enfield & Taylors Lane Power Stations